GR2 has been awarded numerous studies for refinery and chemicals facilities around the globe since 2019. The studies include process optimization, flare and emission reduction, and safety assessment. GR2 has most recently been awarded engineering studies for more than 40 atmospheric storage tanks at a major refinery.

GR2, working closely with the refinery’s safety and operations team, has deployed an innovative, integrated approach to assess the seismic resilience of the refinery storage tanks. GR2’s expert engineering team employs 3D laser scanning technology to create dynamic models of the tanks. The 3D models are integrated with operational and maintenance data. Acquired data are combined with advanced modeling techniques by using Finite Element Analysis (FEA) software for simulating various earthquake scenarios to assess the tanks’ behavior. The assessment of the data requires abundant computing power and specialized expertise on the subject.

Advanced Earthquake Modelling with FEA study aims to provide refiners and chemicals operators to a reliable seismic vulnerability assessment model, along with optimized design parameters, to implement mitigation strategies for such seismic events’ health, environmental, and safety impacts.

Introduction: Atmospheric storage tanks are critical components of various industries, including oil and gas, chemical processing, water treatment, and food production. However, their susceptibility to seismic forces poses significant challenges in ensuring operational safety and integrity. Traditional seismic analysis methods often lack precision, leading to conservative designs or unforeseen vulnerabilities. To address these limitations, a more sophisticated approach is required, combining decades of engineering expertise with high-resolution data acquisition with advanced computational modeling techniques.

GR2 FEA study reports provide a comprehensive understanding of structural behavior of the storage tanks during seismic events to the operators. The availability of such tank assessment for the refinery is an invaluable resource to mitigate potential risks of earthquakes including health, safety, and environmental impacts.

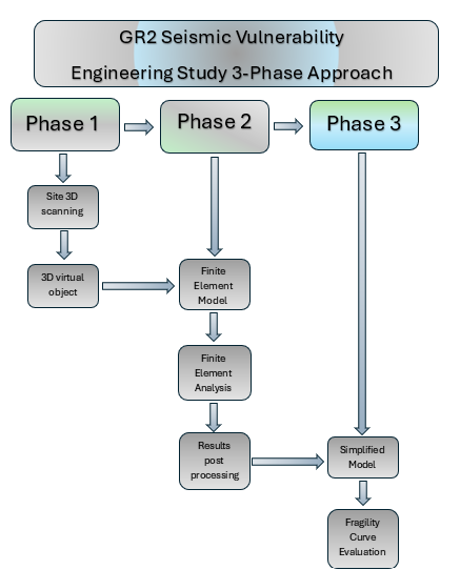

3-Phase Approach Advanced FEA Study: GR2’s advanced earthquake model work executed in 3 Phase approach to obtain fragility curves for the selected tanks based on 3D Laser Scan tank data, FEA simulation and nonlinear analysis with an Incremental Dynamic Analysis (IDA) of probabilistic approach with the following objectives:

- Obtain the maximum filling capacity of the tanks

- Maximize seismic safety

- Reduce computational burden

- Failure modes evaluation

- Fragility estimation

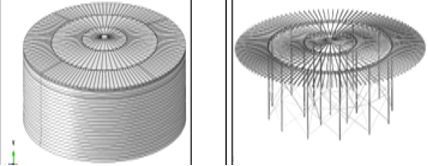

Phase 1 – Site Laser Scan and 3D Model of Tank: Laser scanning technology offers unparalleled precision in capturing the geometry and structural features of storage tanks. By emitting laser beams and measuring their reflections, it generates detailed point clouds representing the tank’s surface topology with sub-millimeter accuracy. These point clouds serve as the foundation for creating 3D models that accurately depict the tank’s geometry, including any imperfections or deformations. Additionally, laser scanning enables the collection of as-built data, providing a comprehensive understanding of the tank’s current condition for precise analysis by creating a 3D model.

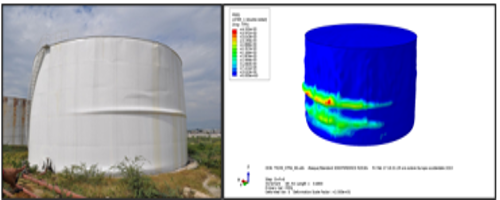

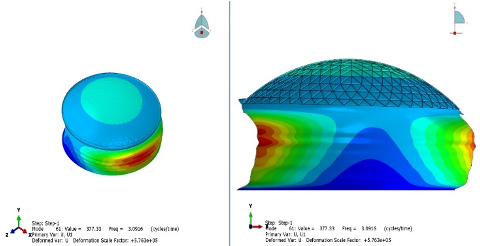

Phase 2 – Finite Element Model, Analysis and Data Processing: Failures in tanks can have different causes and results, such as: Higher value of radius to thickness ratio, small increases in equilibrium behaviors, combination of hoop tensile stress and meridional compressive stress can cause outward deformation and buckling of the tank. Such deformation and buckling can occasionally result in leakage due to weld fracture and, in some cases, total collapse of a tank

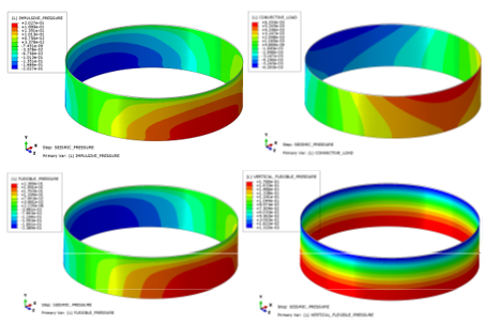

Initially, laser scanning is employed to capture detailed as-built data of the tank, including geometric dimensions, weld seams, and surface irregularities. The integration of laser scanning, and FEA facilitates a holistic approach to earthquake modeling of storage tanks. FEA is a powerful computational technique used to analyze the structural response of complex systems under various loading conditions, including seismic events. By dissecting the tank structure into finite elements and applying appropriate material properties and boundary conditions, GR2 simulates the dynamic behavior of the tank during earthquakes by using FEA software. This simulation allows us to evaluate stress distributions, deformation patterns, and potential failure modes with high accuracy, enabling informed decision-making regarding structural enhancements and retrofitting measures as applicable.

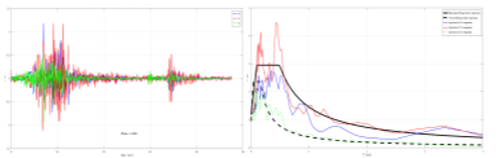

Actual seismic ground motion accelerations simulate earthquake behavior of the tank while the internal fluid to tank interaction also applied as pressure fields. The set of accelerograms are selected from real accelerograms using an accurate database of ground motion software, considering some specific characteristic, for example:

- Content in frequency of signal with similar response spectrum respect to the site design elastic spectrum.

- Range of magnitudes 5 ≤ M ≤ 8.5.

- Distance 0 km≤ R ≤ 100 km (about 62.14 mi) from the specific site.

After introducing the seismic data to FEA software, a precise computational model of the tank is created with realistic boundary conditions and material properties. GR2 runs various seismic simulations to assess the structural response of the tank under different earthquake scenarios, identifying critical areas of vulnerability and optimizing design parameters to enhance seismic resilience.

Phase 3 – Advanced FEA Study Report: GR2 prepares a comprehensive study report for each tank. Integrated FEA models with simulations results can be used to describe a general characteristic behavior of the tank studied under the selected earthquake scenarios considering its inelastic and elastic structural response.

Advanced FEA simulations for all selected scenarios are reported with tank failures.

In particular, the study report addresses for the following points where relevant:

- the convective and the impulsive components of the motion of the liquid,

- the tank shell deformation due to the hydrodynamic pressures and the interaction effects of impulsive component,

- the deformability of the foundation soil and the ensuing modification of the response the effects of a floating roof, if significant and applicable.

Benefits and Applications: GR2’s integrated approach provides several benefits to the operators:

Accuracy: High-resolution data from laser scanning ensures the faithful representation of the tank’s geometry and condition, enhancing the accuracy of seismic simulations.

Precision: FEA provides detailed insights into the structural behavior of storage tanks under seismic loading, enabling engineers to identify weaknesses and develop targeted mitigation strategies.

Compliance: Enhanced seismic analysis capabilities enable organizations to meet stringent regulatory requirements and industry standards for safety and reliability.

Economics: By accurately assessing vulnerabilities and optimizing design parameters, this approach helps minimize retrofitting costs while maximizing seismic resilience.

Conclusion: The integration of laser scanning, and Finite Element Analysis represents a significant advancement in earthquake modeling for storage tanks. By combining high-resolution data acquisition with sophisticated computational simulation, this approach offers unparalleled insights into structural behavior and vulnerabilities. Implementing this methodology enables engineers to develop robust mitigation strategies, optimize design parameters, and enhance the seismic resilience of storage tank infrastructure, ensuring operational safety and reliability in seismic-prone regions.

About GR2 Engineering Inc., Houston, Texas:

GR2 Engineering provides EPC solutions and engineering consulting services to the energy, infrastructure, and chemicals sectors. Contact [email protected] for more information on GR2’s project and engineering solutions.